According to statistics, among my country’s carbon dioxide emissions, the power sector accounts for 40% of total emissions, industrial emissions account for 30%, and construction and transportation each account for 15%. The industrial sector consumes more than 60% of society’s energy, and energy-intensive enterprises such as steel, building materials, petroleum, and chemicals account for 80% of industrial carbon dioxide emissions. It can be seen that energy-intensive enterprises are the main body of carbon emissions and the backbone of promoting carbon peak and carbon neutrality.

As the “dual carbon” strategy enters the practical stage, reducing carbon emissions, implementing energy revolution, and industrial revolution have become hot topics in the manufacturing industry. The effectiveness of “dual transformation” of low carbonization and digitalization has also become an important measure of the core competitiveness of manufacturing companies. .

Sine Electric has always focused on the field of industrial automation and is committed to helping upstream and downstream enterprises in the industry chain implement “dual carbon” practices by building low-carbon and sustainable industry solutions.

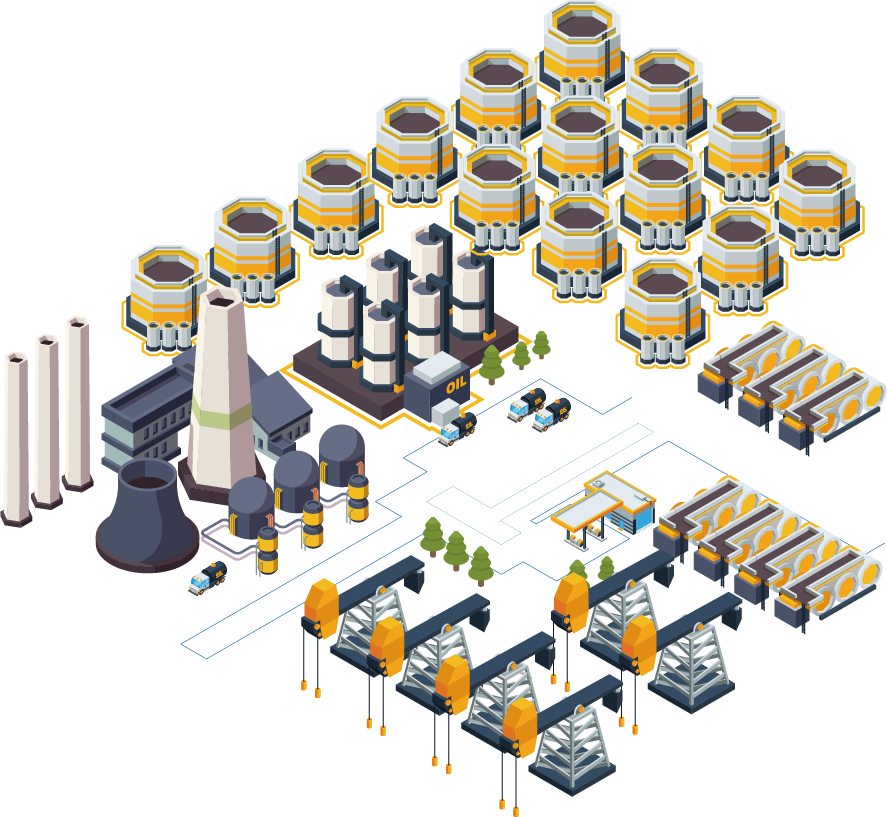

Sine Electric helps the petrochemical industry

Sine Electric is deeply involved in oilfield technology, proposing intelligent control according to process requirements, customizing direct-drive screw pump solutions, energy-saving beam pumping unit control solutions, winch pumping unit control solutions and other energy-saving solutions for the petrochemical industry

In 2018, Sine Electric became a Class A supplier of China National Petroleum Corporation. In 2019, Sine Electric cooperated with General Electric of the United States in the field of oil field energy-saving technology to serve Changqing Oilfield. In the past ten years, Sine Electric’s technical service products have been used in Daqing Oilfield, Liaohe Oilfield, Songyuan Oilfield, Shengli Oilfield, Dagang Oilfield, Huabei Oilfield, Changqing Oilfield, Karamay Oilfield and other units, providing one-stop solutions for the petrochemical industry.

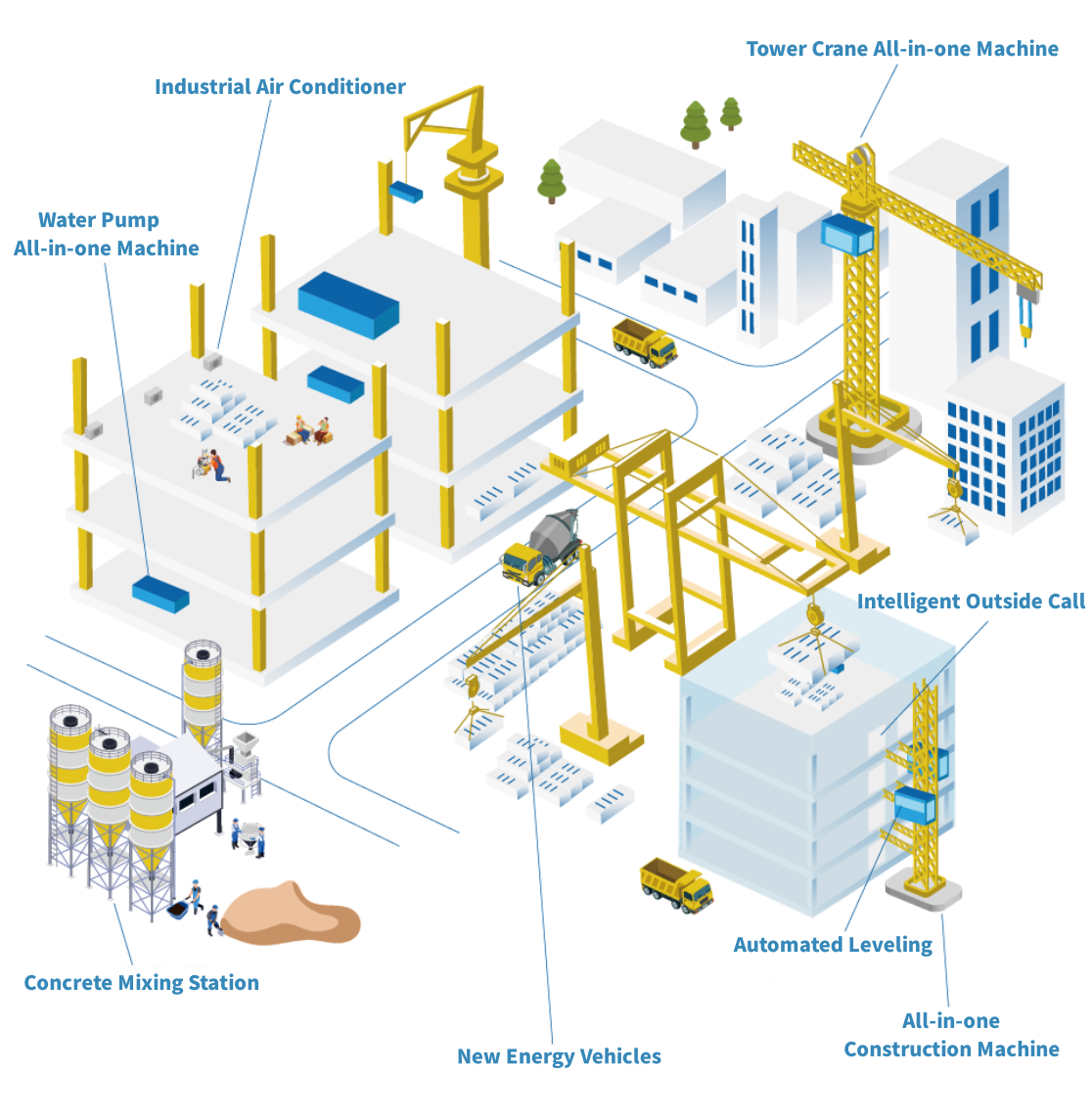

Sine Electric helps the construction industry

The domestic construction and real estate industries have moved from the incremental era to the stock era. How to carry out the renovation of the building stock and save energy and increase efficiency has become the focus of exploration by all parties. Sine Electric’s special aircraft for the construction industry adopts an intelligent system and is stable and reliable, which greatly improves the efficiency of building construction and effectively reduces energy consumption, helping the construction industry achieve the goals of energy conservation, emission reduction, efficient management and sustainability.

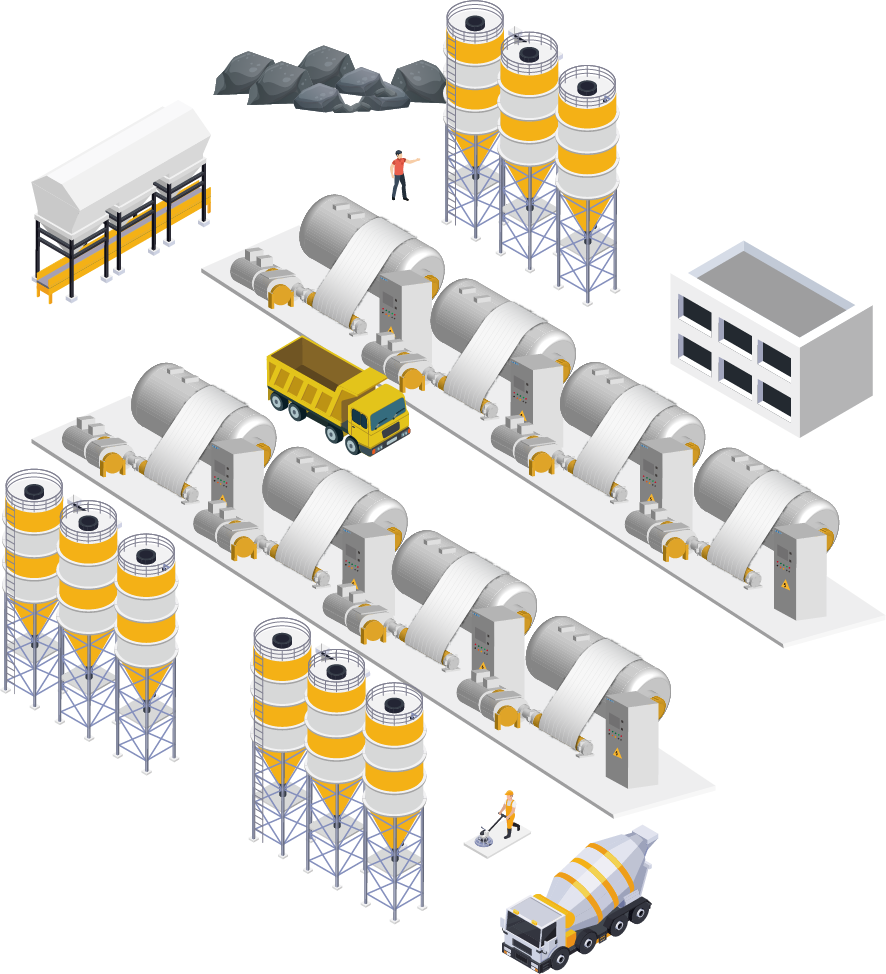

Sine Electric helps ceramic machinery industry

In view of the complex and harsh working conditions on-site in the ceramic industry, the ceramic machinery solution developed by Sine Electric adopts excellent systematic cooling, high protection level, easy maintenance and other designs to achieve more stable, reliable, safe and energy-saving equipment operation control, and effectively Improve the intelligence level of ceramic equipment.

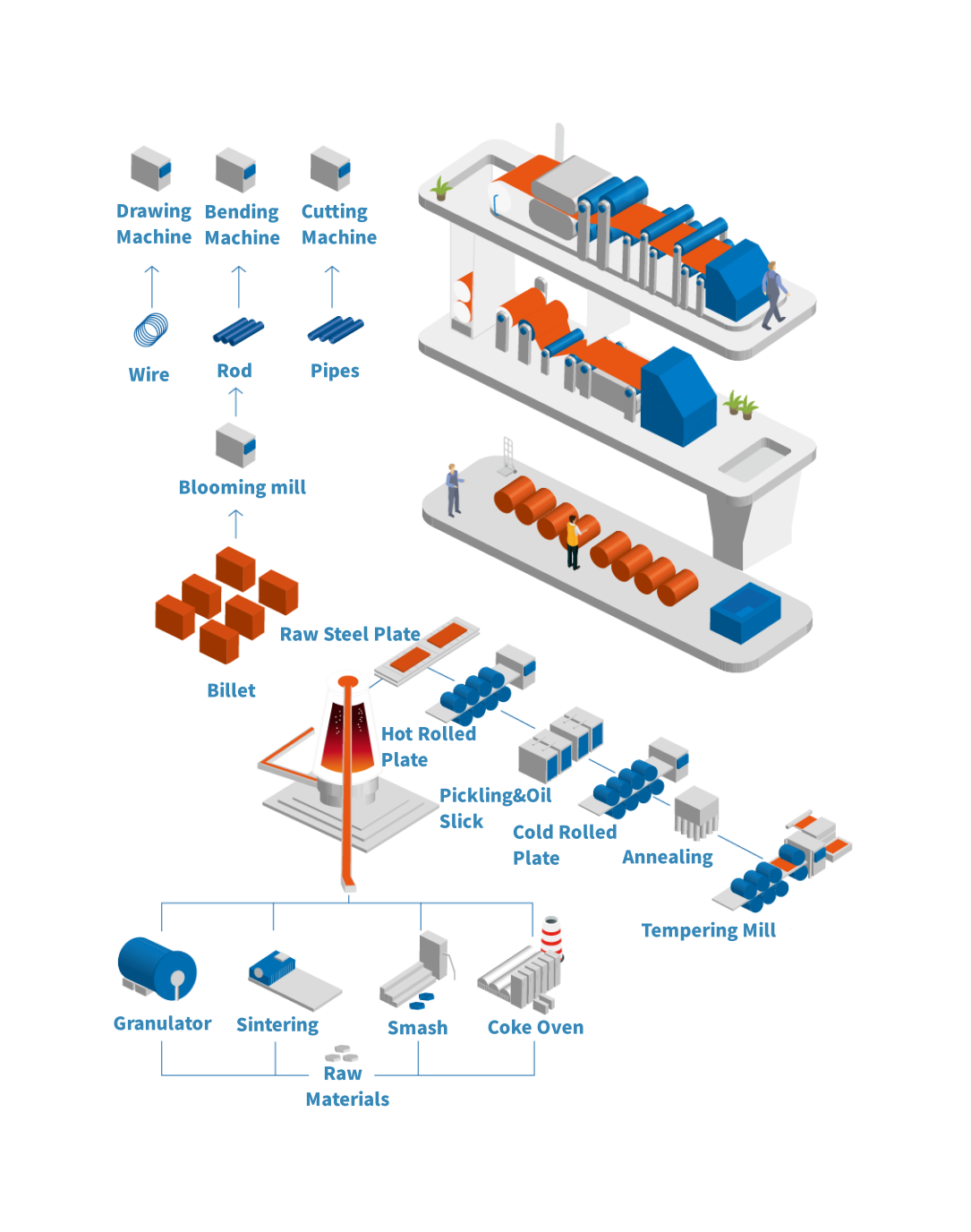

Sine Electric helps the steel processing industry

Sine Electric EM760 series products support open-loop vector control and closed-loop vector control of asynchronous motors and synchronous motors, and are widely used in the steel processing industry. In process applications such as steel plate and aluminum plate rewinding, straightening machines, and rolling mills, high-precision speed control ensures various The rollers run synchronously, and the soft and stable torque control ensures constant tension on the material. The low-frequency full-load start and 200% overload capability adapt to a variety of working conditions, playing an irreplaceable role in improving product accuracy and green energy saving.

Sine Electric helps smart factories

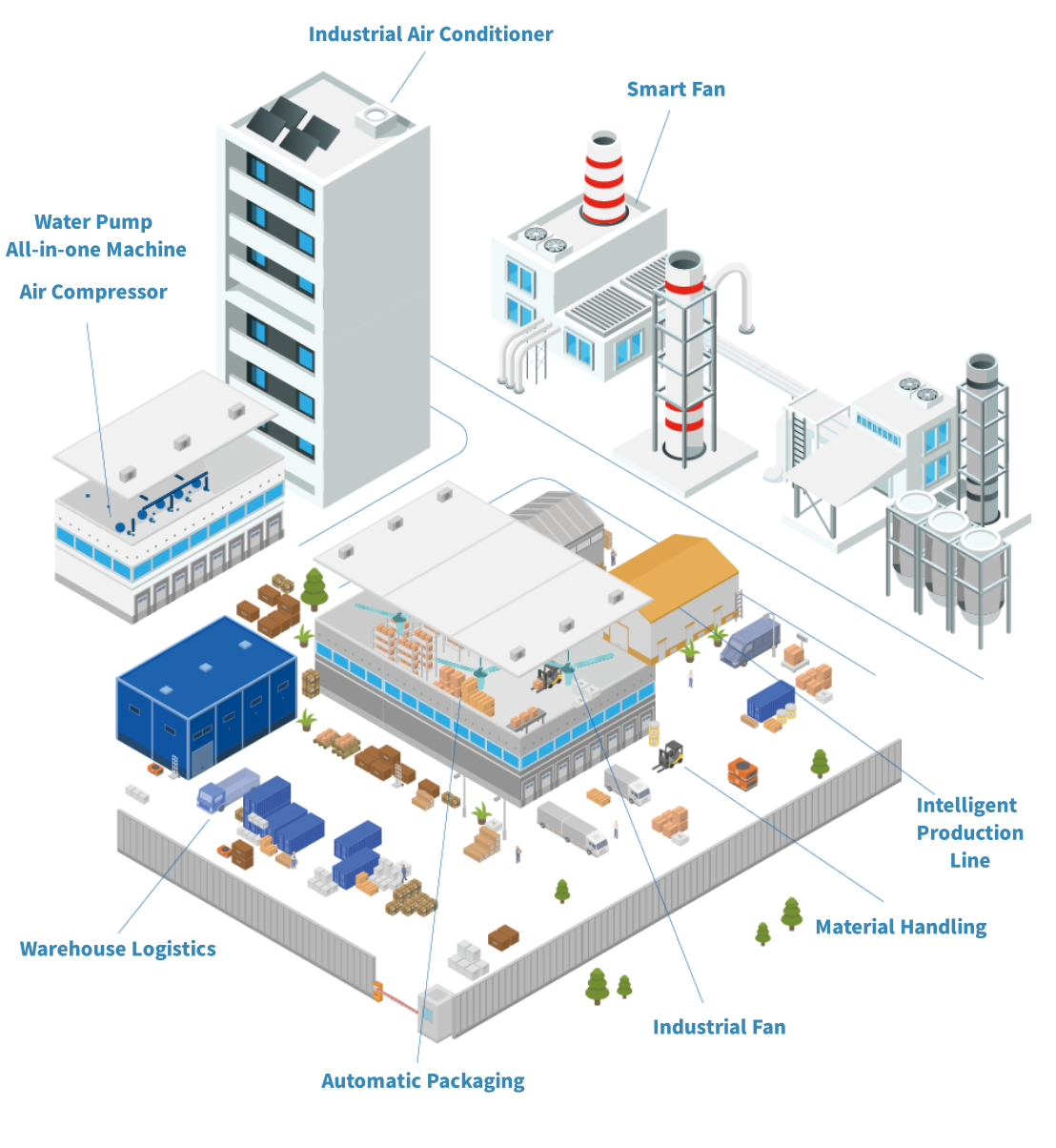

Smart factories focus not only on the electromechanical equipment on the production line, but also on public facilities such as HVAC, lighting, power transformation and distribution, and compressed air systems that provide a comfortable environment for factories and offices. Sine Electric’s smart factory solutions help factory buildings achieve energy optimization and save operating costs, which will bring more possibilities to modern smart factories.

Achieving the ” dual carbon” goal is a broad and profound change. As a practitioner of green development, Sine Electric has been running on the road of green revolution to reach the peak of carbon emissions. With its excellent independent research and development capabilities, it has customized energy-saving and emission-reduction solutions for industry customers on the basis of general products. Products are widely used in lifting machinery, logistics equipment, petrochemical industry, wires and cables, plastic machinery, textile machinery, woodworking machinery, air compressors, CNC machine tools, printing machinery, packaging machinery, metal rolling, building materials, ceramic equipment, fans and pumps and other industries to help enterprises accelerate their progress in the direction of green, energy-saving and carbon reduction.